Powering Performance from Pit to Port

At Mine Supply International, we specialise in delivering premium conveyor and wear solutions that keep mining operations running smoothly across the Asia-Pacific region.

With over 40 years of industry experience, we understand the challenges of the mining sector. Our solutions are designed to enhance efficiency, reliability, and safety, ensuring continuous performance across the whole production chain

Driven by a commitment to quality, durability, and service, we support our clients with expert knowledge and industry proven solutions, helping them move forward with confidence.

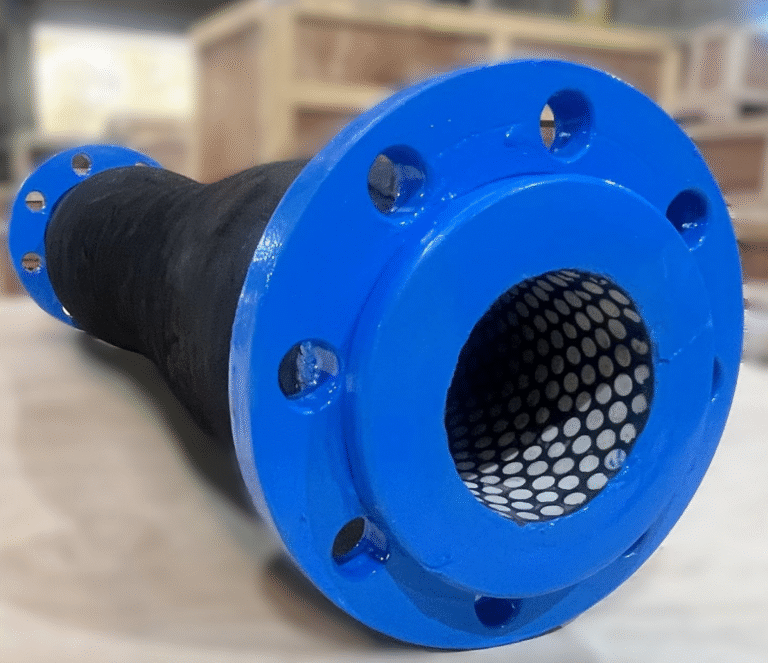

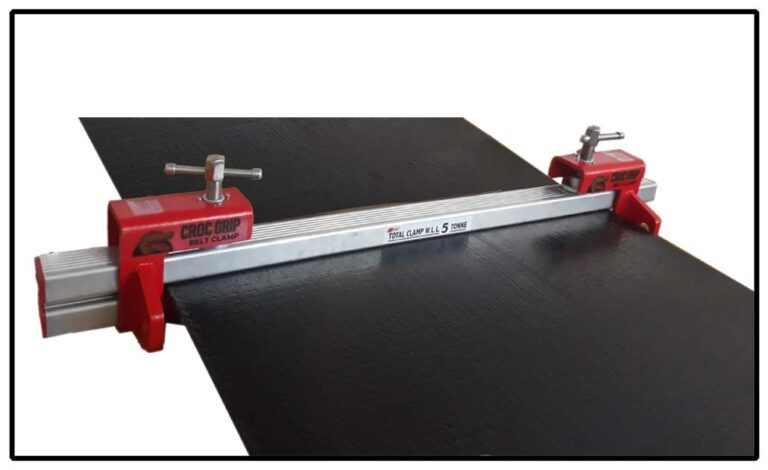

Products

We supply a system wide range of materials handling solutions, covering everything from wear protection and flow control to belt repair and splicing. Selected to support the full life cycle of plant and equipment in heavy industry.

Contact Us

Get in touch to discuss supply, support or site solutions. We’re here to help.

- +61 488 780 243

- support@minesupplyint.com

Global Footprint

We operate across major mining regions, including Asia, Australia, South America, and Africa. This broad international presence allows us to deliver timely solutions and maintain close alignment with the needs of resource projects around the world.