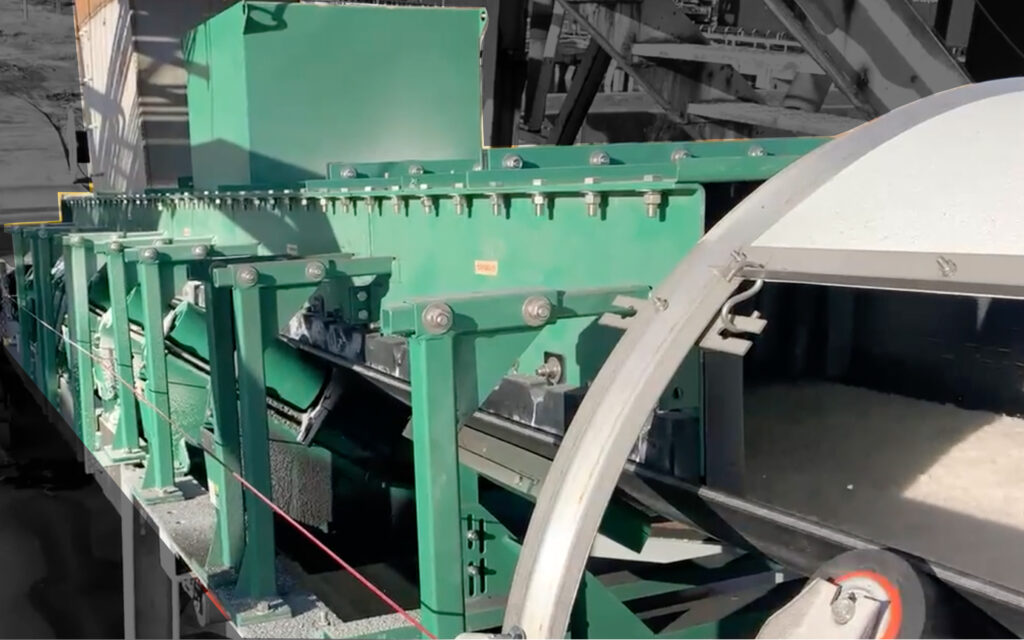

Load Zone Solutions

Bulk material handling operations often struggle with cost control and efficiency, especially in conveyor load zones. Poorly designed zones can cause product loss, equipment damage, and increased maintenance. Richwood provides customized solutions that address these issues by evaluating each application for cost-effective performance.

From basic impact protection to advanced dust containment, Richwood’s systems deliver proven ROI. Their reliable solutions ensure safer, more efficient load zones with measurable savings.

Optimizing Conveyor Load Zone for Efficiency and Cost Savings

Experience superior conveyor performance with Richwood’s engineered load zone systems. Designed for durability, safety, and efficiency, our solutions minimize downtime and maximize material control.

Why Choose Richwood Load Zone Solutions?

- Minimise spillage and dust to create a cleaner, safer work environment.

- Engineered for durability, reducing wear and maintenance frequency.

- Solutions tailored to match your material type and site conditions.

- Boost efficiency and lower cost per ton with every load handled.